The Challenge

How can tractor drivers ease their workloads and increase efficiency at the same time?

Farm equipment keeps getting smarter, that’s plain to see. Modern tractors are much more advanced than they were 30 years ago. The same goes for implements like balers, plows, seeding machines, and fertiliser spreaders. And yet… farmers can’t reap the full benefit of technology if tractors and implements don’t work well together. In fact, operators can be left having to control two very advanced machines at the same time, resulting in a lot of time-consuming and repetitive tasks.

Solution

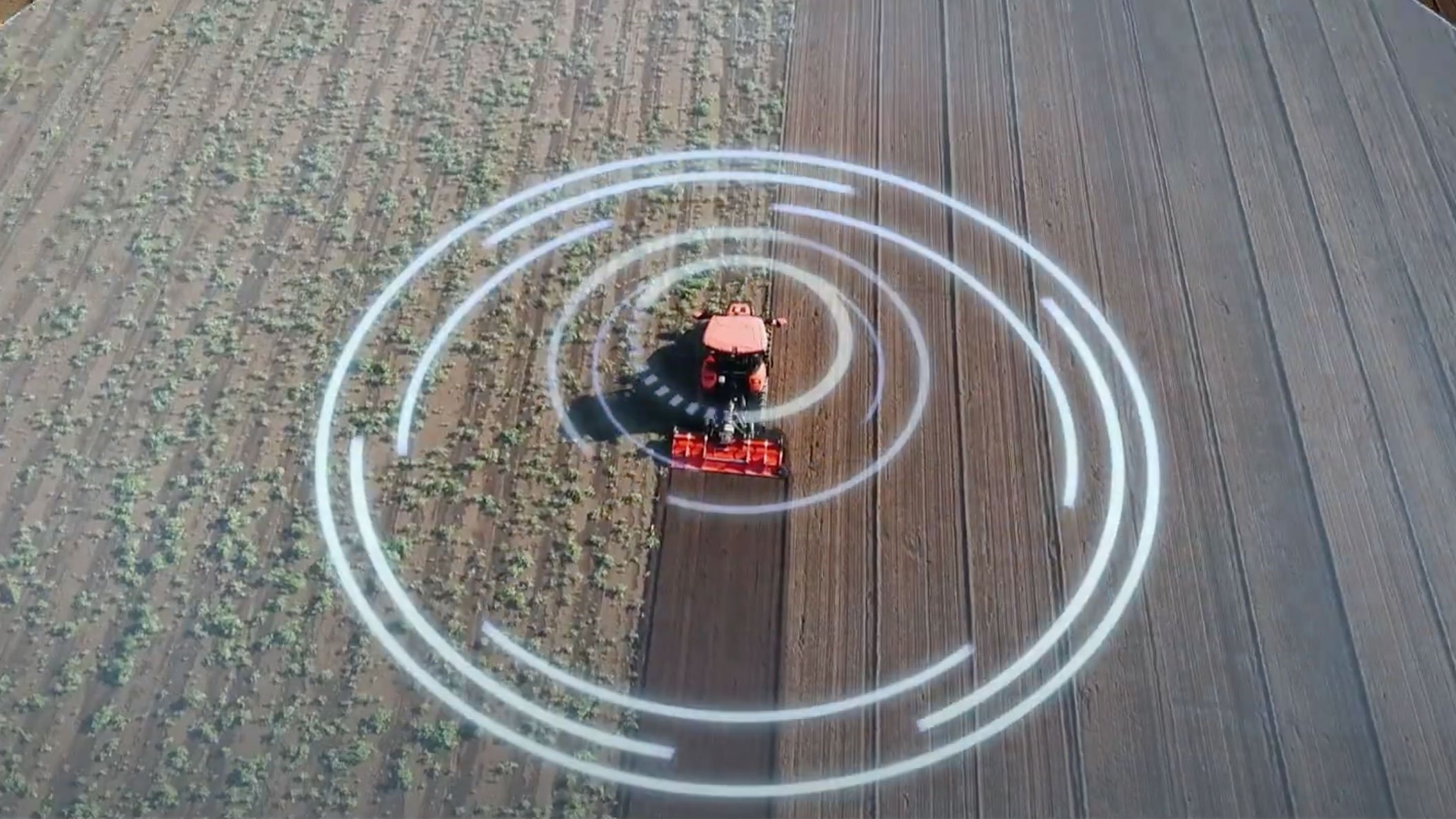

A smarter way for tractors, implements and operators to work together.

So how do you get tractors and implements to cooperate? Can they work as a team? At Kubota, we like to start with the human factor when we think about smart farming. That means the first beneficiary of technological advance should be the operator. We also have to think about the concept of cooperation more broadly and that’s why we are core members of the Agricultural Industry Electronics Foundation (AEF). The AEF is an independent organization that brings together important manufacturers and associations with the aim of improving cross-manufacturer compatibility of electronic and electric components in agricultural equipment.

In 2009, the AEF started working on secure communication between machinery from different manufacturers. The result was TIM, the Tractor Implement Management (TIM). It is a cross-product and cross-manufacturer ISOBUS solution, that enables the implement to control certain tractor functions. Tractor Implement Management (TIM) automates a number of operations which need the coordination of the tractor and implement and thereby saves the operator a lot of repetitive and tiring work.

A good-quality tractor with a good-quality baler can do fantastic work, but they depend highly on the skill-set of a very busy driver, repeating routine actions over and over. A day of baling can be very long, and each bale can typically require ten steps. With Tractor Implement Management (TIM) onboard, the operator only has to concentrate on the first two steps.

The Tractor Implement Management (TIM) really comes into its own in baling operations where the working windows are often narrow due to weather conditions. The work is completed more quickly and with higher bale quality. Contractors and large farms in particular benefit from the user-friendliness of the technology, which can be quickly mastered by operators.

Not only does Tractor Implement Management increase the operator’s comfort, it also increases the quality and efficiency of the work and saves time. Based on the current design, baling operations are streamlined to help reduce braking, starting the binding, engine speed changes, accelerating, etc.

It also increases efficiency by automatically detecting the best times for necessary operations, such as when the bale chamber is full or when the tailgate needs to be opened or closed. Manual delays or errors are significantly reduced.

Letting the implements do the work.

Tractor Implement Management (TIM) uses the ISOBUS interconnection “language” to communicate between tractor and implement. It even allows communication between the agricultural equipment of different manufacturers. Whereas in other tractor-implement systems the tractor controls the implement, here we have bidirectional communication. In other words, the implement can control tractor functions such as forward speed. The implement requests the services it needs from the tractor in order to operate in the most efficient way.

Implements available in Europe that work with Tractor Implement Management (TIM).

Tractor Implement Management (TIM) is an open ISOBUS automation solution set up by the Agricultural Industry Electronics Foundation (AEF). It works with AEF-certified tractors and implements. You can easily find a range of tractors and implements from different manufacturers that are compatible with Tractor Implement Management (TIM) functions at www.aef-isobus-database.org. To use it, you need to unlock the system with a licence, which can be purchased from your dealer. Some Kubota tractors, like the M7003 come with Tractor Implement Management (TIM) as an option and can be controlled not only by Kubota’s Tractor Implement Management (TIM) round baler, but by all AEF-certified Tractor Implement Management (TIM) implements.

Benefits

“The technology is really easy to use even for non-experts.” Jean François Vanel, Farmer, Normandy, France.

Jean François Vanel and his wife run a farm in Normandy with 200 acres of grain crops plus 125 acres of hay for their organic beef cattle. He told us about his baling: “We are doing 2000 to 3000 bales per year. We are doing long tiring working days, and it’s always good to get rid of numerous repetitive actions when doing round bales.

The Tractor Implement Management (TIM) technology is really useful on this point, as the baler and tractor can manage the actions by themselves. The technology is really easy to use even for non-experts.”

Explore Other Stories.

How should we address the great challenges of our time? Can we shape a better future together?

We want to lead the way with innovative solutions.

Implement Command® Improving Tillage Control

10/14/2022

READ MORE

Agri Robo MR1000A The Labor Saver

10/14/2022

READ MORE

Concept Tractor

10/14/2022

READ MORE